Help

Community21 has selected some case study communities and projects to share across the network to inspire and inform others. Should we be featuring yours? If so get in touch.

Location - Workspace is based in the city of Eindhoven, Netherlands.

Background - First started in 2013 by a man called David Hakkens. Hakkens has invented ways of reducing plastic wastage around the world. (Preciousplastic.com, 2019). Machines have been developed in order to boost recycling. This project has formed a global community through Hakkens traveling and using the internet in order to become more known (Dave Hakkens, 2019). Hakkens uses old ship containers as his workshops

Social Impacts - Since this project has started Hakkens has developed blueprints for his machines which has allowed more people around the world to join in on his work and creations. This has been achieved through Hakkens website becoming more well known.

Economic Impacts - Through promoting this project, it has been receiving hundreds of monthly donations. Also, thousands of single donations have been made to help support this project. The products created from the plastic can be sold which creates a small amount of profit for some communities.

Environmental Impacts - Furthermore, this project has been working in the Maldives. Precious plastics have recently joined with Parley for the oceans in order to reduce the amount of plastic pollution in the ocean as this is has become a great concern.

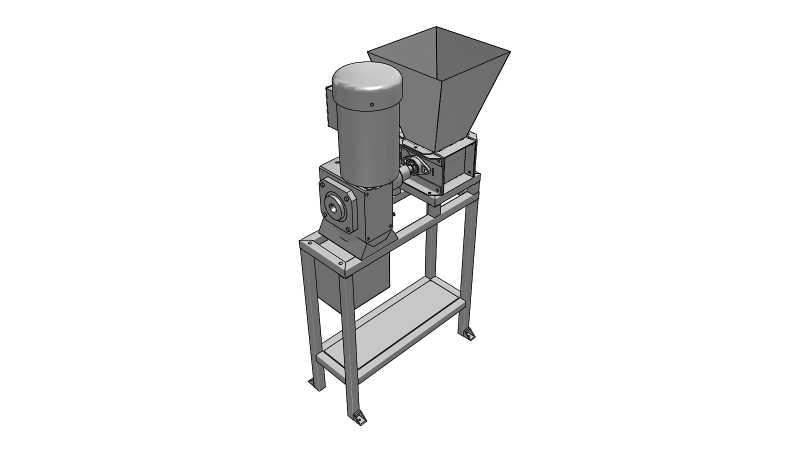

Equipment: - Shredder: This machine "allows you to shred plastic into small flakes" which you can then "easily wash", "store" and "transport" to other workspaces to make "products" (Precious Plastics Community Platform, 2020). (Instructions: https://community.preciousplastic.com/academy/build/shredder)

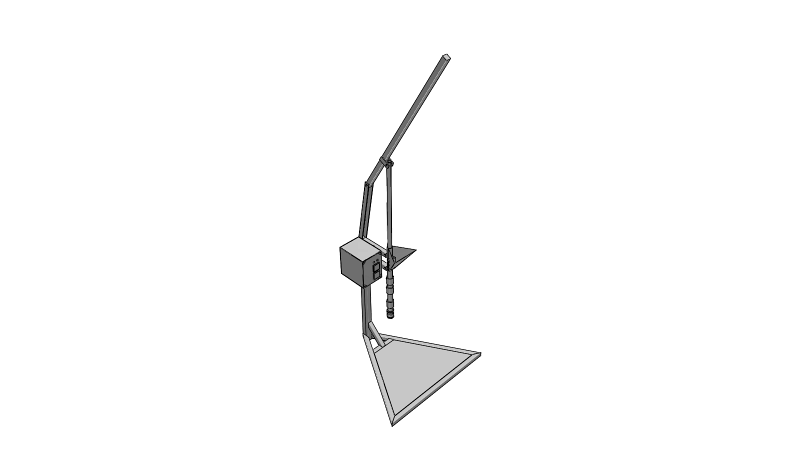

-Injector: "Shredded plastic enters the hopper and is heated and pressed through a long barrel into your mold" (Precious Plastics Community Platform, 2020).

(Instructions: https://community.preciousplastic.com/academy/build/injection )

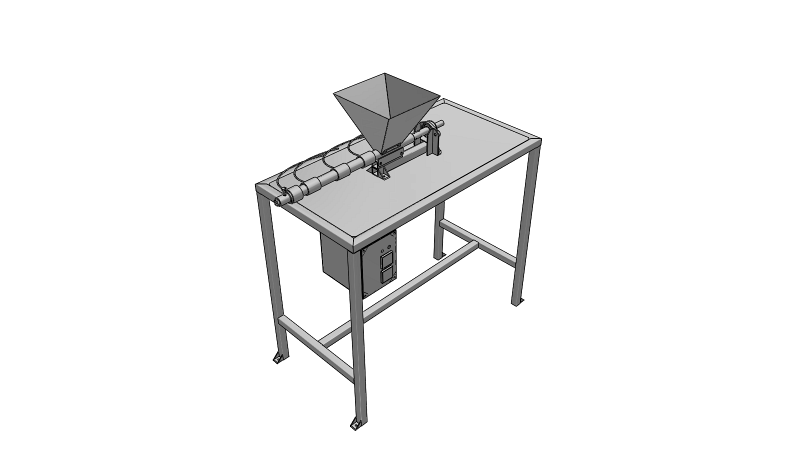

-Extruder: "Extrusion is a continuous process where shredded plastic enters the hopper, heated and pressed with a screw through a long barrel. The output is a steady line of plastic, and as this machine runs continuously, if you have enough plastic and a well-streamlined process you could (technically) be recycling 24/7. With this machine you can create filament (challenging but doable), granulate or get creative and spin this continuous line around a mould, and is great for educational purposes as the process is very straightforward and easy to understand. When plastic is extruded it nicely blends different colours together and produces a homogenous and clean colour" (Precious Plastics Community Platform, 2020).

(Instructions: https://community.preciousplastic.com/academy/build/extrusion )

-Compression Machine: "The compression machine is basically an electric kitchen oven to heat the plastic, and a compression mechanism (a carjack) to apply pressure to your mould. The process is slower than the other Precious Plastic machines but it allows for larger moulds to be used. It can be used to create raw material, like sheets or shapes that can be further worked on to make new products and gives a specific flake-like look to the plastic (which looks amazing!)" (Precious Plastics Community Platform, 2020). (https://community.preciousplastic.com/academy/build/compression )

Products:

-Shelf: Made using "the extruder and the injection machine" (Precious Plastics Community Platform, 2020). (Instructions: https://community.preciousplastic.com/how-to/make-your-shelf)

-Bird Feeder: "Made with recycled plastic and Precious Plastic extruder" (Precious Plastics Community Platform, 2020). (Instructions: https://community.preciousplastic.com/how-to/extrude-a-bird-feeder )

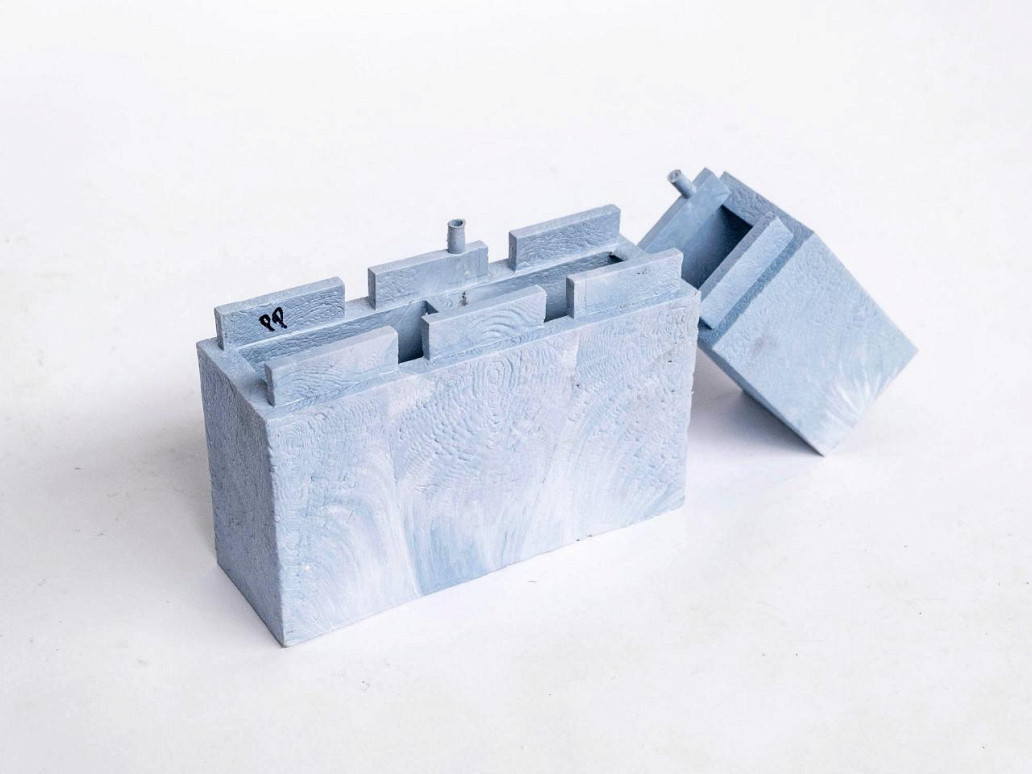

-Plate: Involves making a "Aluminium mould for injecting a plate" (Precious Plastics Community Platform, 2020). (Instructions: https://community.preciousplastic.com/how-to/inject-a-plate)

-Plastic Extruded Bricks: Uses the extruder to make plastic bricks "to replace more conventional and wasteful building materials" Precious Plastics Community Platform, 2020). (Instructions: https://community.preciousplastic.com/how-to/make-extruded-plastic-bricks )

References: