Help

Community21 has selected some case study communities and projects to share across the network to inspire and inform others. Should we be featuring yours? If so get in touch.

Name: Bintang

Location:Cigadung, Bandung City

Specialist materials:Plastic

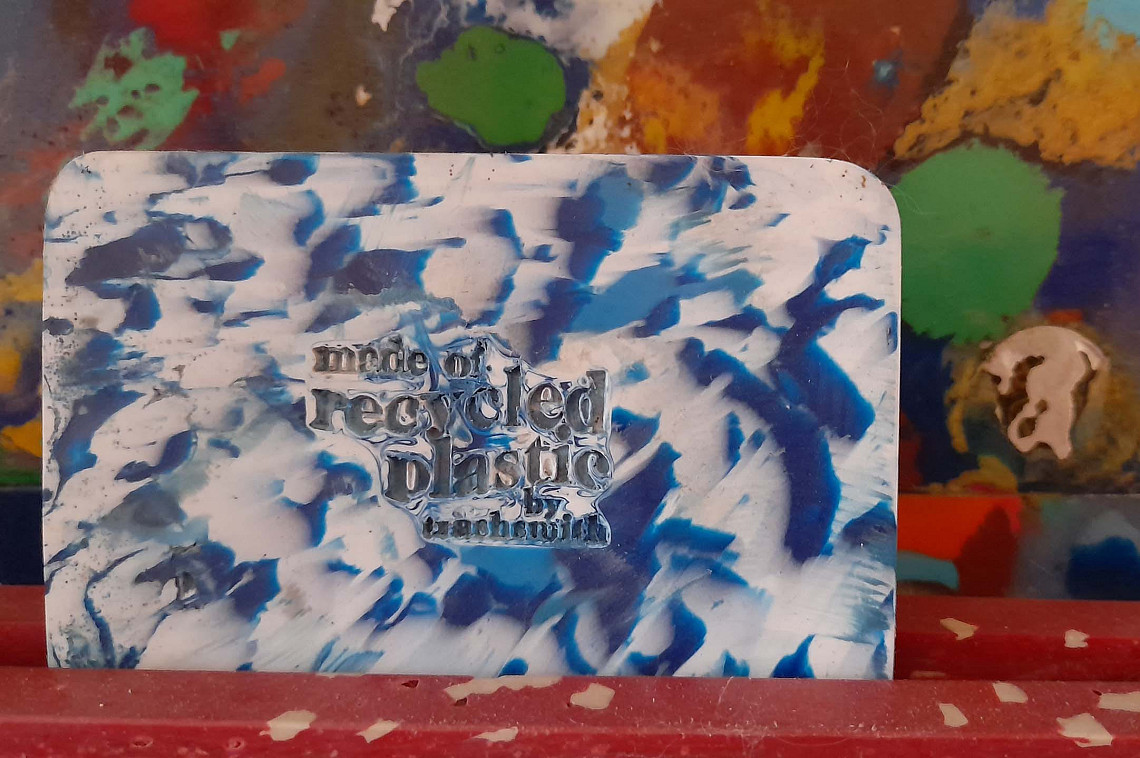

Products:Ashtray, Skateboard, Notebook, Coaster, Shelf, Button

Links [if available]:https://instagram.com/trash.smith?igshid=YmMyMTA2M2Y=

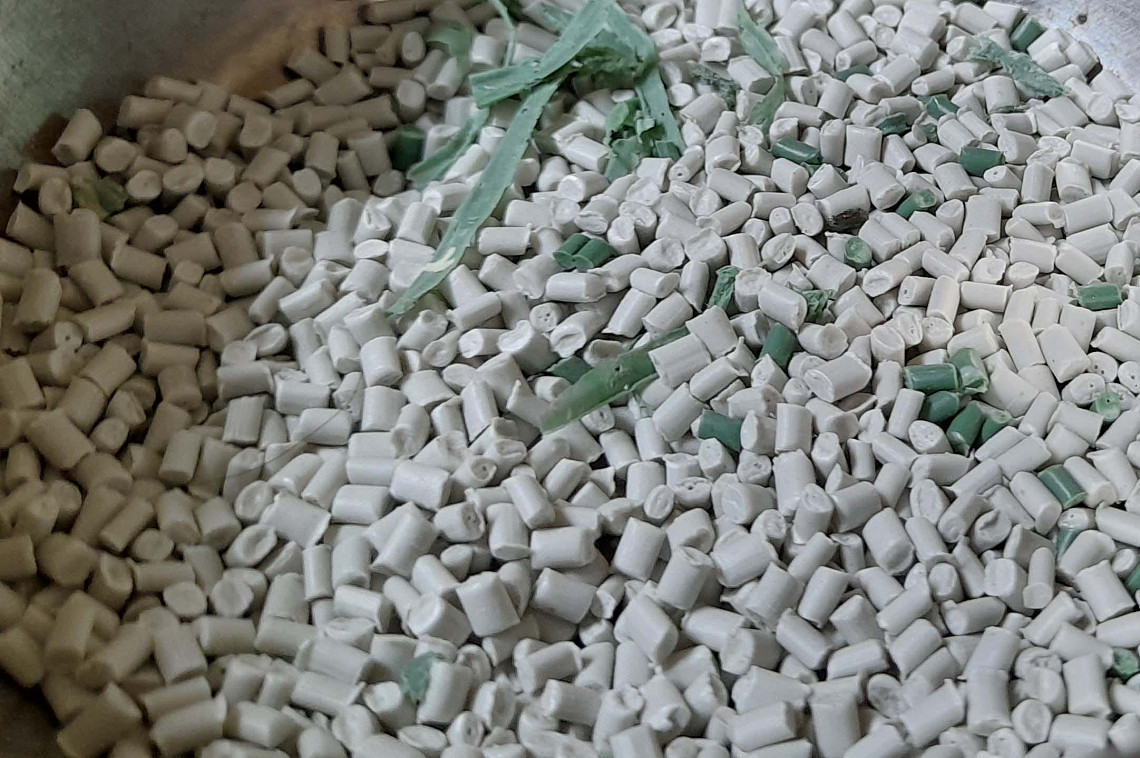

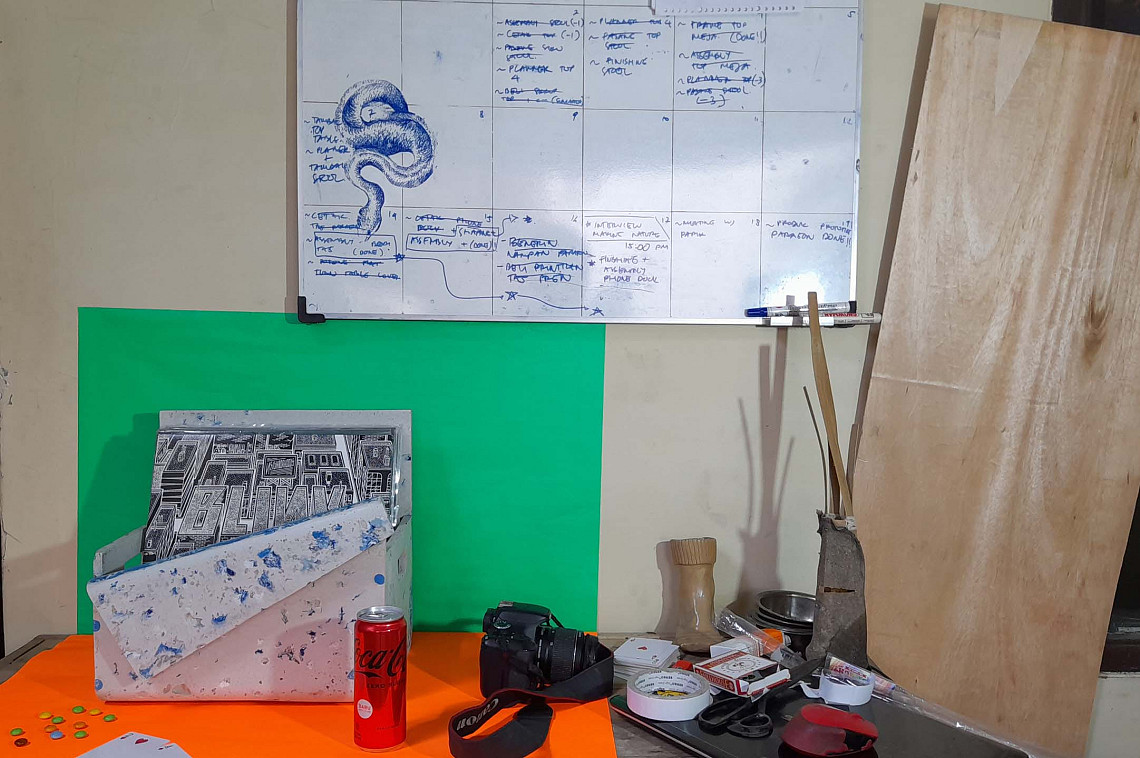

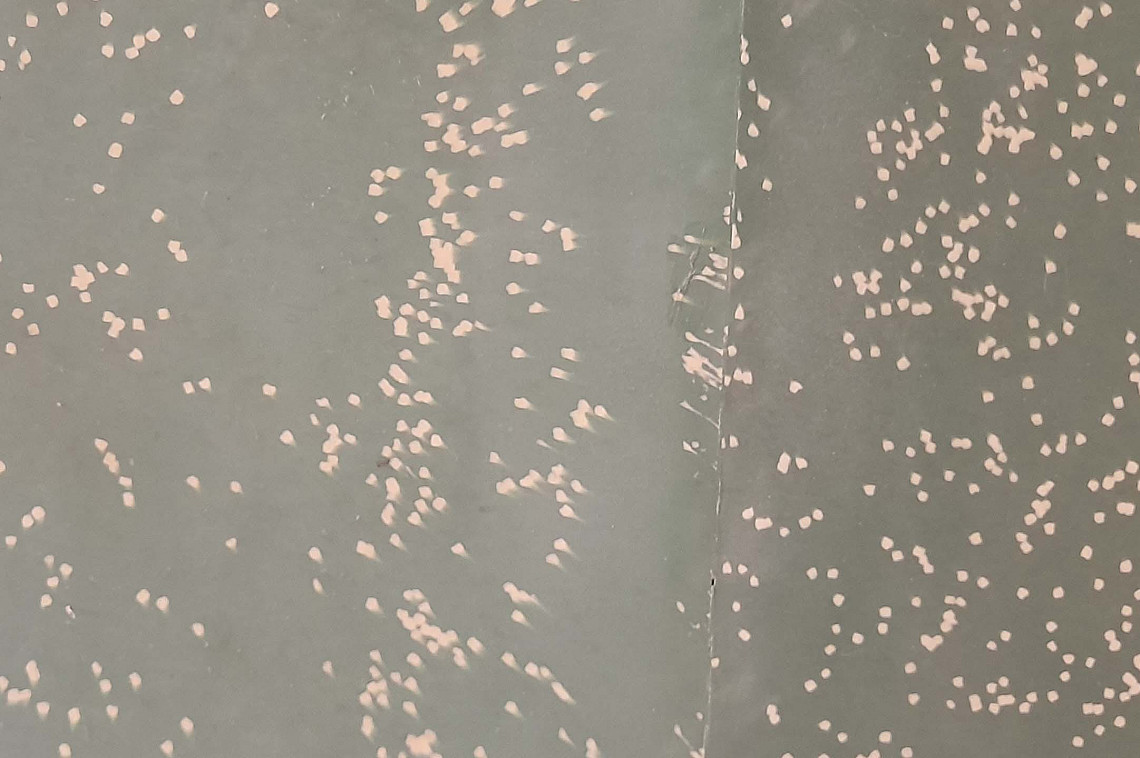

Mr.Bintang is one of the founders of Trash.Smith, a brand in Bandung that focuses on processing plastic waste. His interest in plastic waste materials emerged from practical work activities at the Innovation Hub in 2017 which was held at Green School Bali. Adapting the Precious Plastic program, he learned how ordinary people can actually process plastic on a home scale without using big industrial machines. In his final college assignment, he made hydroponic pots from recycled plastic. There are two raw materials that are usually used to make Trash.Smith crafts. First, there is polypropylene plastic which is commonly found in the form of plastic bottle caps, oil caps, and cosmetic packaging caps. Second, there is polyethylene plastic, which is usually found in the form of gallon caps and shampoo bottles. Most of the raw materials are obtained from collectors and special industries for plastic crushers. Usually, Mr.Bintang buys plastic that has been chopped because it is more readily available. Sometimes, Mr.Bintang also gets the raw materials from refill drinking water depots, coffee shops, and friends. “I took it from a coffee shop owned by a friend of mine. I collaborate with him. I take his garbage, so that he doesn't have to spend money to manage his waste,” he said. That way, both parties gain benefit, and expenses can be minimized. In the process, plastic that has not been chopped will usually be washed and dried first. Then, they are chopped and put into handmade mold. Next, The mold is put into the oven for the melting process, and after that it will be pressed. After that, wait until the product cools down so that it can be removed from the mold. Waste from the manufacture of products in Trash.Smith is almost non-existent, because even the smallest bits can be reused and made into other products. There are four craftsmen in the workshop. The knowledge of the craftsmen on how to treat plastic waste continues to grow and increase along with the research and experiments carried out. The craftsmen often conduct experiments first to determine the suitability and quality of the materials. This is because the characteristics of each type of plastic are certainly different. Even though the product is made of plastic waste, its durability is unquestionable. There are almost no weaknesses and problems in the product care. "The product is safe even when it is exposed to the sun, weather, and water, because in nature plastic is very difficult to decompose," said Mr.Bintang. This durability; the characteristic of plastic waste that is difficult to decompose in nature, are then utilized by Mr.Bintang to make new items that are durable even when they are reused.