Help

Community21 has selected some case study communities and projects to share across the network to inspire and inform others. Should we be featuring yours? If so get in touch.

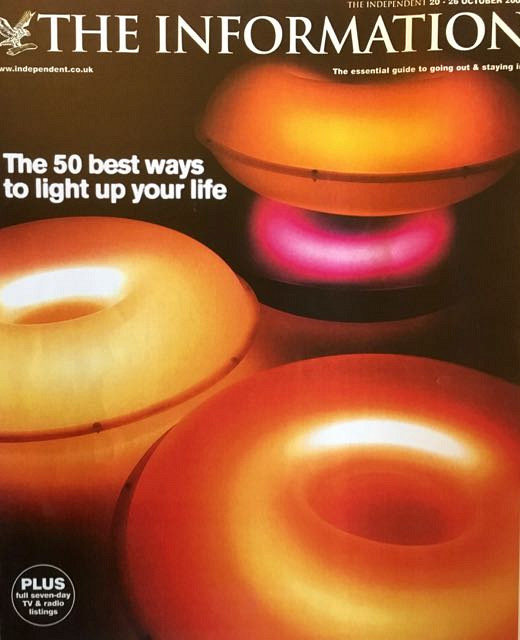

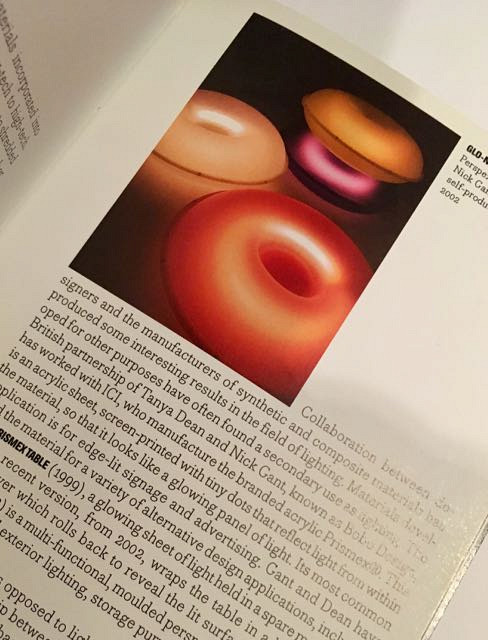

Early adoption of take-back processes between material converters and the material manufacturers (Perspex TM). The inherent ease of recycle-ability of the material and its performance characteristics facilitate products that demonstrate multi-functionality, energy and material efficiencies, design for disassembly and material reuse in product and consumption cycles.

This work was created by Nick Gant and Tanya Dean (Studio BoBo) as consultants to the iconic Perspex brand.

Disassembly and circularity: Single material manufacture and ease of disassembly: By exploiting the formability and strength of the acrylic the product can be manufactured from one single material that is 100% recyclable and due to take-back manufacturer networks facilitated by the material manufacturer it can efficiently returned to base material and / or reshaped into another product. This is an early example of circular economy thinking.

Efficiencies:

The design demonstrates efficiencies through the use of single material, energy efficient manufacture and the use of what was then early adoption of new generation efficient lighting - all afforded by the material performance and characteristics of plastics (Perspex).

The material performance attributes enable a monocoque structure which illuminates but is strong enough to easily support the weight of a person. So innovative lighting and seating is combined.